Production Loss Analysis Software

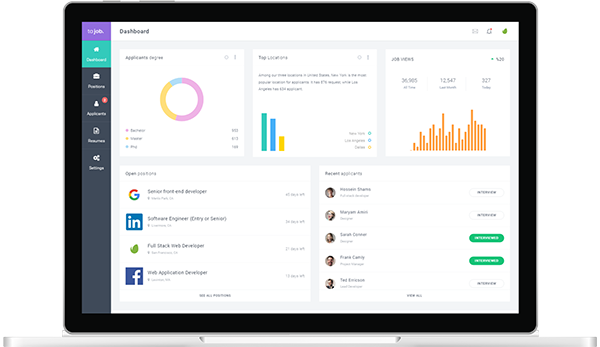

Factory management needs to know the potential losses in a factory. Production Loss Analysis Software lets you compute this anywhere in the world with ease. It uses the Loss Scoreboard to measure the difference between the actual cost of a period being considered and the plan cost of all resources that make up the factory.

PRODUCT OVERVIEW

Systematic Approach To Production Loss Reporting And Cost Control

Factory Configuration

The software dashboard expects to get a well-defined and hierarchical multi-level structure of the factory, highlighting its sub-elements. The technology and number of employees responsible for each sub-element are also inputted.

Cost Calculation

Here, the production and cost analysis are calculated and allocated into four significant resources. This analysis is used to compare the difference between plan cost and actual cost via diagrams and dynamic charts.

Loss Identification and Breakdown

At this point, it is easy to see the difference between plan cost and the actual cost with interactive charts. With weights populated in the charts, a concise production loss reporting is achieved.

Reporting

The filtering of data and representation in Pareto charts is possible here. It is now easy to find losses that occupy a significant proportion. Here is an answer to the production loss reduction in the manufacturing industry.

Connect with Production Loss Analysis Software

It does not matter the challenges you have when it comes to production loss analysis and control; our production loss analysis software is up to the task. All you have to do is reach out to us, and we will provide a lasting solution in no time.

What make PLAS different?

01

Focus on how much a factory loses

Unlike traditional OEE, which focuses on manufacturing productivity, PLAS considers your factory losses as a whole by comparing the actual cost and the planning cost.

02

Deep dive on the total loss

PLAS reveals precisely how much your factory is wasting and divides them into nine significant loss elements. From this information, managers can have a comparative analysis of what is being wasted the most.

03

The significance of the loss categories

PLAS allows managers to add loss categories that happen during manufacturing processes and how much they occupy in the total loss in terms of value.

04

Comprehensive Reporting

PLAS generates interactive Pareto charts based on dynamic data filters that managers can choose to serve their reporting purposes. Pareto Charts always show the loss elements in highest to lowest order.

What makes Production Loss Analysis Software different?

Production Loss Analysis Software is a dedicated software that carries out production and loss analysis and presents the data in simplified and familiar formats like charts.

Focus on how much money your factory lost

Production Loss Analysis Software focuses on the factory as a whole to compare the actual cost and the plan cost in the manufacturing process – something traditional OEE cannot do. This unique process makes it easy to visualize how much your factory has lost.

Same Factory, Multiple Version

Due to the flexibility of the Production Loss Analysis Software, users have the opportunity to create and configure multiple versions of their factories. And when the question “how many versions are possible” is asked, “unlimited” is the answer you get.

Well-structured categories to separate loss causes

Production Loss Analysis Software uses a unique production loss reporting mechanism. Loss causes are divided into two categories; main loss causes and sub loss causes. All loss causes are then explained by four significant resources. They are machines, material, human labor, and energy.

Comprehensive Reporting

Manufacturing loss management rests solely on easy visualization of reports in real-time. With Production Loss Analysis Software, detailed, and dynamic data reporting is made possible with Pareto charts. Users can use data filters to choose among the many options and reorder variables as they dim fit.

Everything you need to set up and manage your factory

Structure your factory

A list of areas, lines, and machines of your factory will help speed up the factory configuration.

Data Preparation

Provide value to areas, lines, and machines parameters to calculate plan cost

Know your actual cost

Provide data on the actual cost to compare with the plan cost.

Keep track of the losses

Keep records of loss causes that you can identify during the period considered. Add them to the software and visualize the proportions they make up.

![]()

Unique Pricing

You no longer have to calculate the number of users in your management team or pay for licenses you might end up not using. With Production Loss Analysis Software, cost control is easy, and you have unlimited user access with an all-in-one pricing model.

View Pricing